👷What are safety incidents?👷

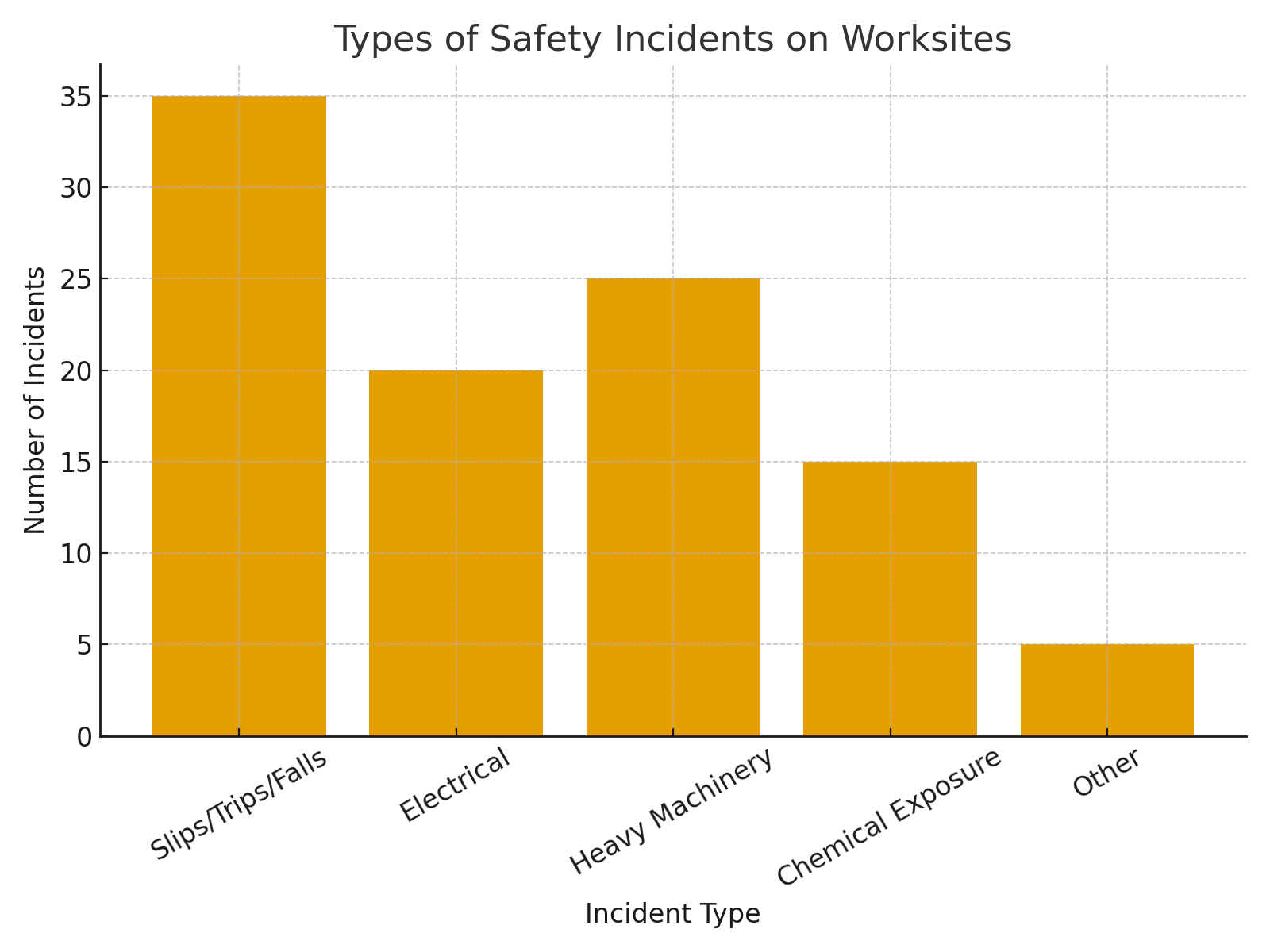

Safety incidents are unplanned events that can cause harm to workers, damage equipment, or interrupt operations. They range from minor injuries (like slips, trips, and falls) to severe accidents involving heavy machinery, electrical systems, or hazardous materials. For example, an electrician receiving a shock due to faulty lockout/tagout procedures.

Nevertheless, every contractor knows that safety is negotiable, but it still does not stop incidents on the worksite, despite all that training and compliance requirements. The hardest part is determining and understanding the root of those circumstances - “Why the Incident happened in the first place and how to prevent them from happening again?”. Pattern recognition is the best answer. With AI Agents, companies can transform the way they operate and avoid workspace accidents.

“According to OSHA, slips, trips, and falls account for 27% of workplace injuries (OSHA, 2022).”

🔍 Route cause🔍

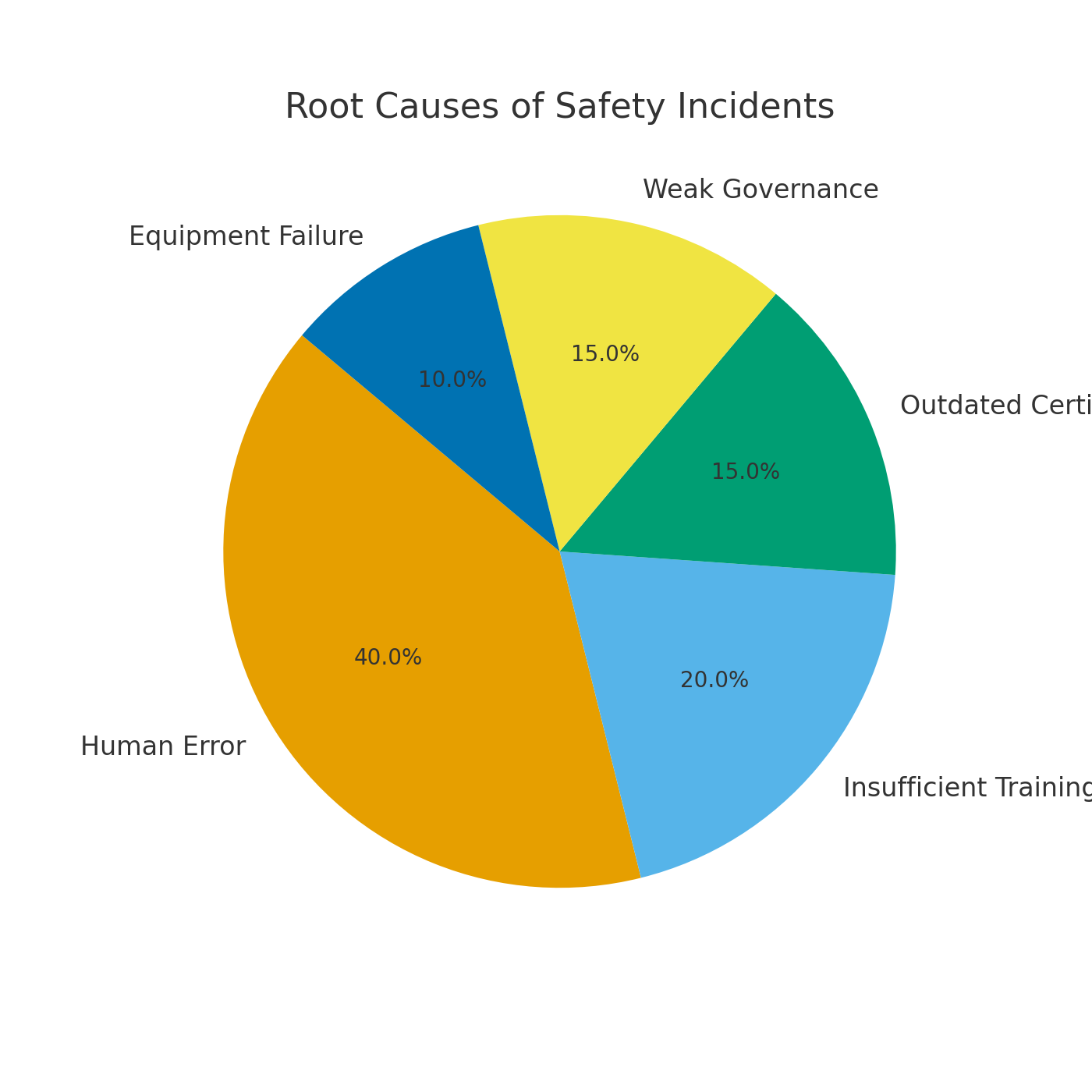

Safety incidents rarely have a single cause; they usually result from a chain of factors. Common contributors include human error—like skipped steps, fatigue, or miscommunication—along with insufficient training and uncertified workers. Weak governance, outdated compliance checks, and poor oversight further compound risks, while equipment failures and incomplete hazard assessments make incidents more likely.

“Research from NIOSH highlights fatigue as a leading human error factor in safety incidents (NIOSH, 2021).”

📈 Solution 📈

AI agents like Aden help contractors go beyond surface-level investigations to uncover hidden patterns in safety data.

Here’s how Aden can transform RCA:

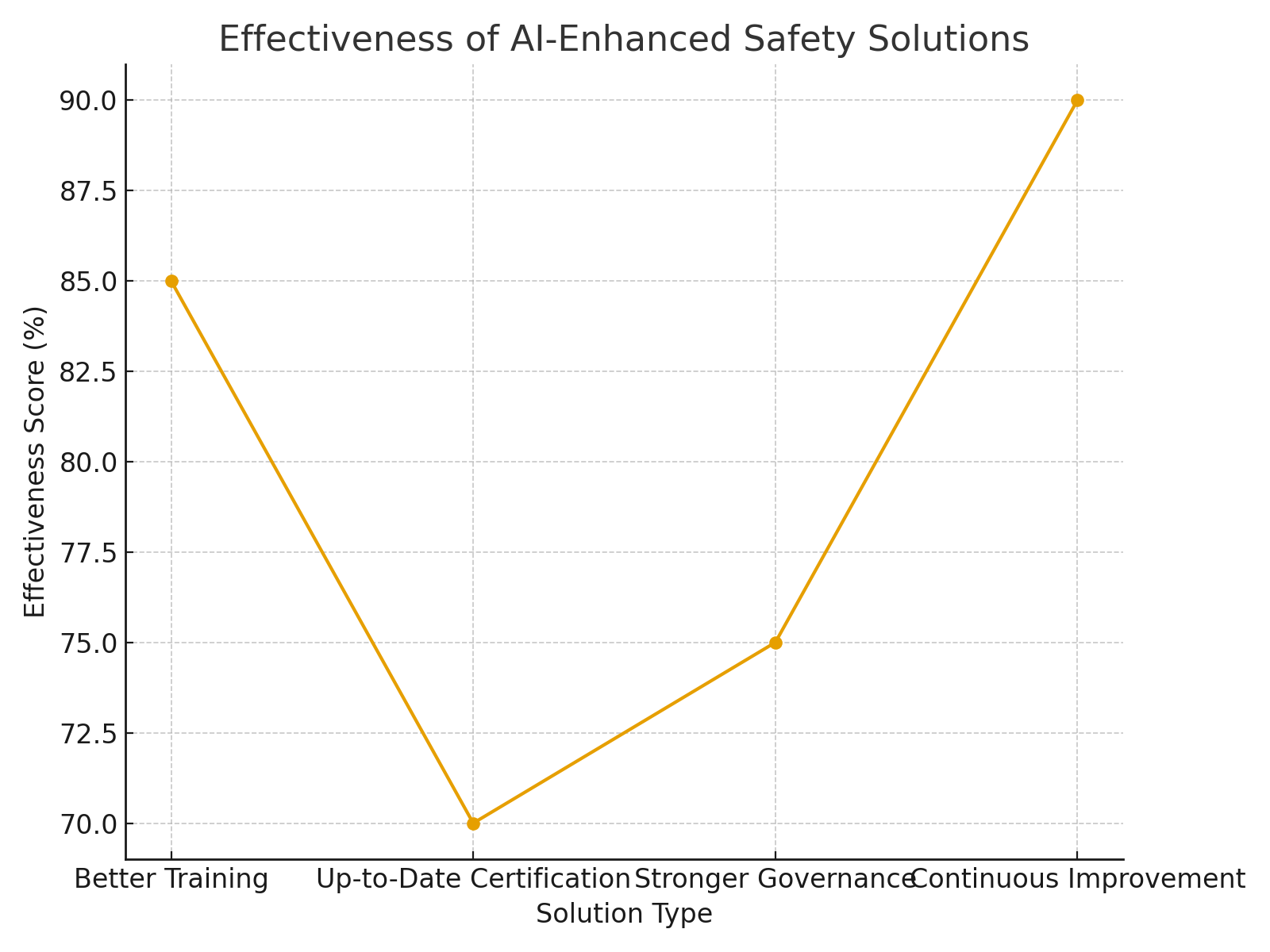

- Better Training: Aden can analyze past incidents to identify common gaps in training and recommend tailored learning modules for crews. Instead of generic safety refreshers, workers get the exact training they need.

- Up-to-Date Certification Tracking: Aden continuously monitors certification records. If a worker’s OSHA, welding, or electrical license is about to expire, Aden can flag it automatically—before it becomes a risk.

- Stronger Governance from Management: Aden provides real-time dashboards that show trends in near-misses, recurring risks, and compliance gaps. This gives management the visibility to step in early and enforce accountability.

- Continuous Improvement: By pulling from incident logs, equipment data, and even sensor feeds, Aden learns over time. Every incident or near-miss sharpens its ability to predict and prevent future risks.

“McKinsey’s 2023 report on AI in construction shows predictive analytics can cut incident rates by 20%.”

🔍 Tutorial🔍

You can check out our tutorials here:

Instead of taking weeks, this analysis happens in hours.

Safety is too important to leave to slow, manual processes. With Aden, contractors can investigate smarter, train better, and prevent incidents before they happen.

👉 Sign up for a demo or schedule a call with Aden’s team today to see how AI-driven safety can protect your crews and projects.