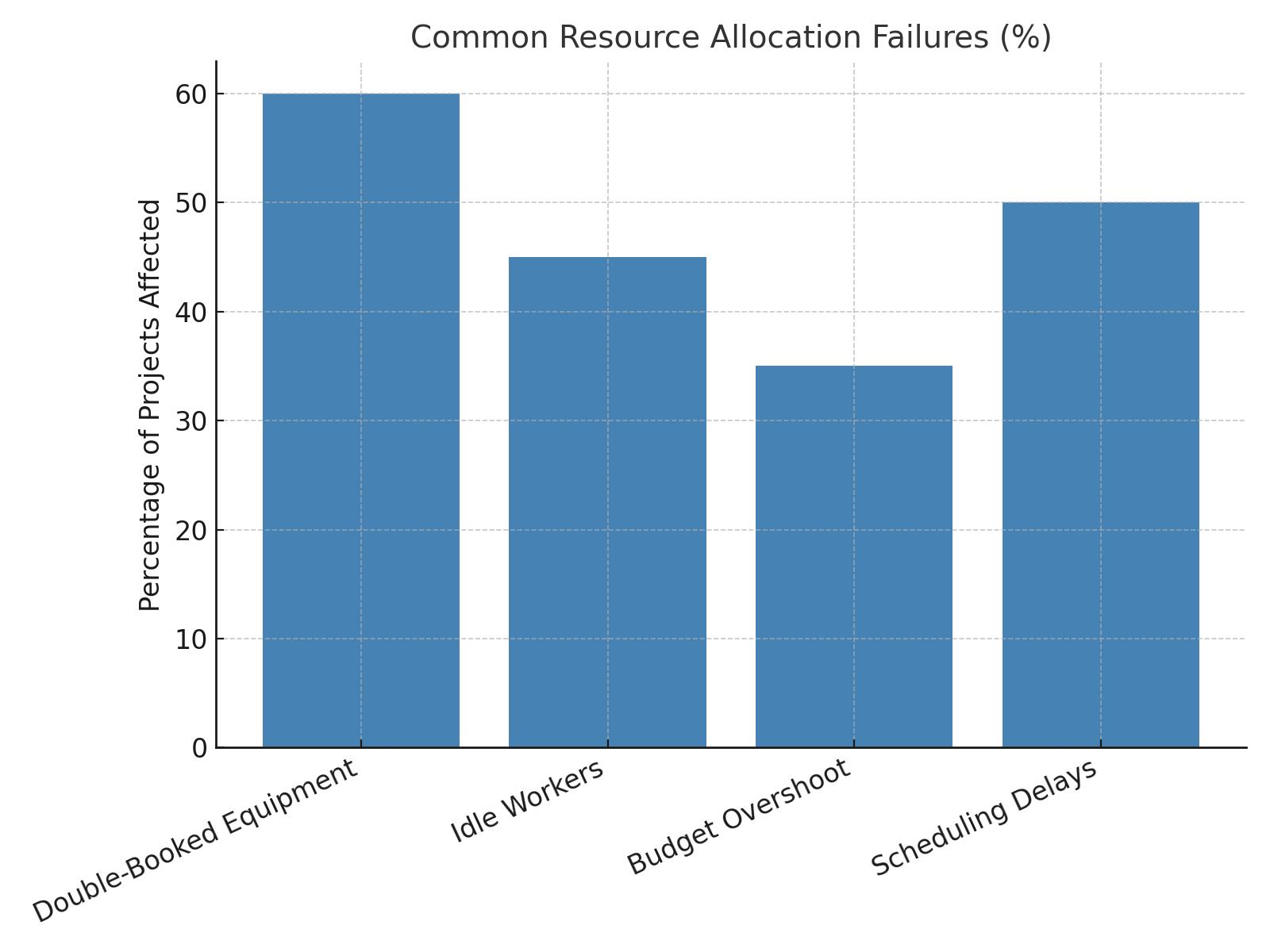

📖 What is Resource Allocation Failure?

When people, machines, time, or money are mismanaged, resource allocation failure occurs in project management, resulting in bottlenecks, idle assets, or cost overruns.

📌 Examples:

- A crane is double-booked across two construction sites, creating downstream delays

- Skilled engineers sit idle because prerequisite tasks weren’t finished on time.

- Budget gets misallocated, forcing last-minute reassignments and cost spikes

ProSymmetry states that lack of visibility into resources is a key driver of project overruns (ProSymmetry, 2024).

PMI highlights that poor resource allocation is one of the leading causes of project delays and failures in multi-project environments (PMI, 2023).

💡 Root Causes of Resource Allocation Problems?

Here’s how an AI-driven resource allocation system works in practice:

- Import Project Data – Schedules, task dependencies, resource pools, and cost data are ingested into the AI platform.

- Baseline Forecast – AI builds a resource forecast using historical performance and task dependencies.

- Simulation of Bottlenecks – “What-if” models stress-test the schedule (e.g., a supplier delay or unplanned absence).

- Optimization Suggestions – AI recommends shifts: reassigning workers, adjusting task start times, or redistributing equipment.

- Dynamic Reallocation – As execution data flows in (via IoT, ERP, or manual updates), AI continuously revises resource plans.

Mosaic research shows that failing to account for resource fluctuations leads directly to cost overruns and schedule slips (Mosaic, 2024).

🧪 Solution Proposal: How AI Optimizes Resource Allocation

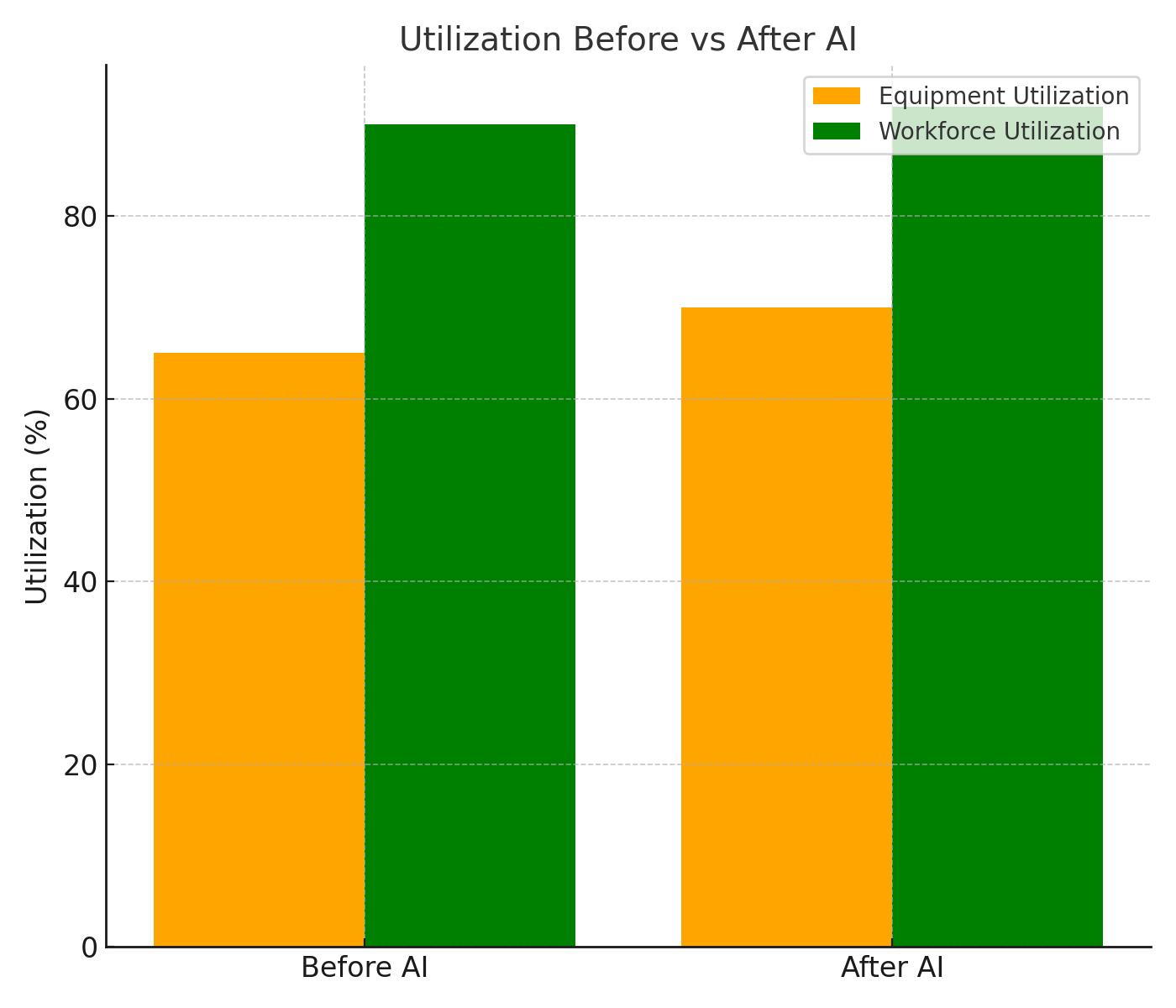

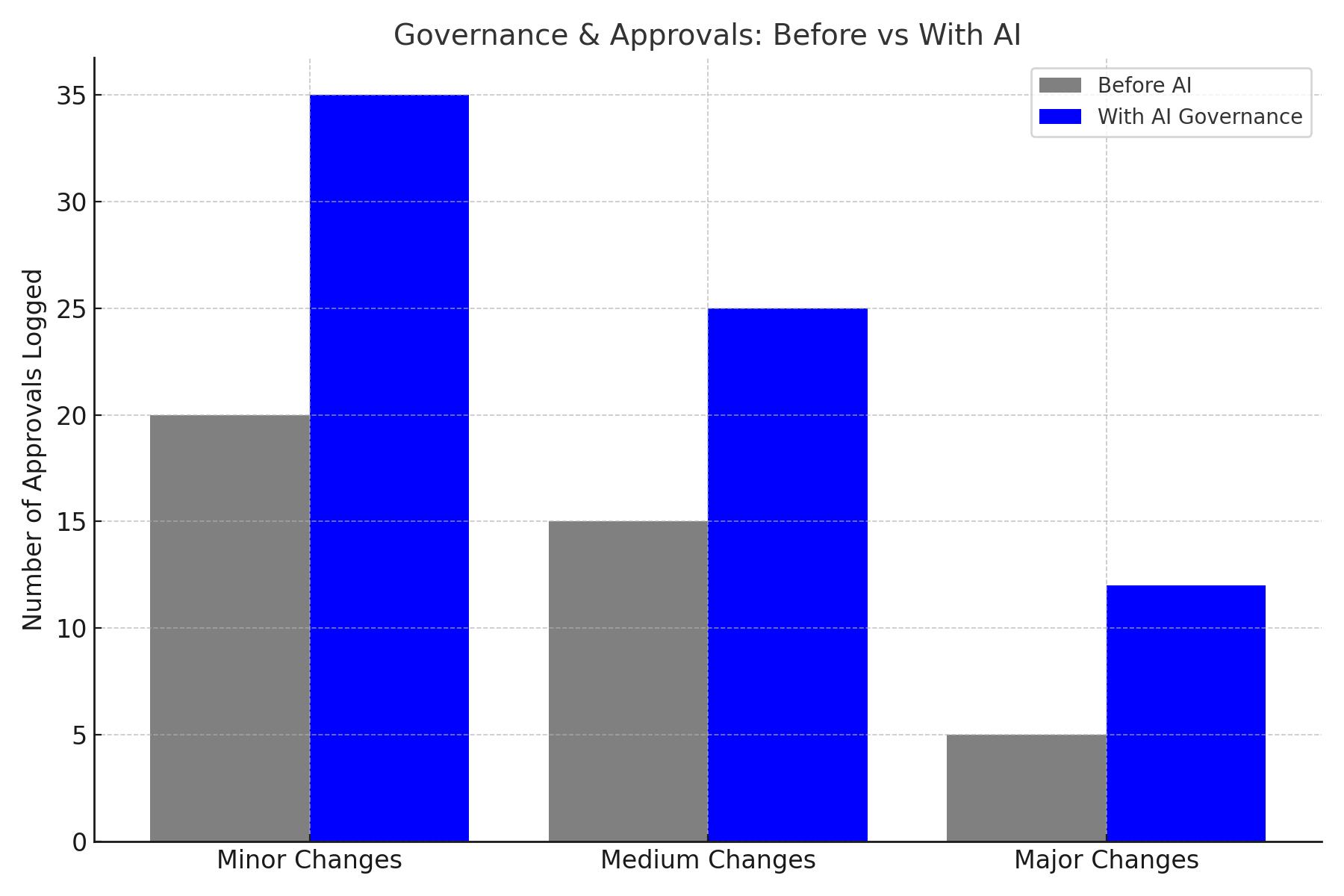

AI enhances resource allocation by turning static plans into dynamic systems:

- 🤖 AI-driven Workforce Scheduling: Machine learning models predict demand for specific roles and auto-assign shifts, balancing workloads while avoiding idle capacity.

VelocityEHS reports AI tools modernize contractor safety management, improving compliance while reducing overhead (VelocityEHS, 2025).

- 🏗️ Equipment Utilization Optimization: AI tracks real-time usage, preventing double-bookings and ensuring high-value equipment is assigned where it has the highest ROI.

Capella Solutions notes that AI optimization in manufacturing improves equipment utilization and aligns resources with strategic objectives (Capella Solutions, 2024).

- 🔄 Real-Time Reallocation During Execution: If a task slips, AI automatically suggests reassignments (e.g., moving a crew from a delayed site to another task that can start early).

- 🛠️ Predictive Maintenance: Models forecast machine breakdowns, ensuring resources aren’t wasted waiting for repairs and minimizing downtime.

🛠️ Tutorial: Do You want to Test it?

Want to see how Aden works in practice?

👉 Check out our walkthrough:

🚀 Ready to see AI eliminate wasted time and idle resources in your projects?

Book a free demo with Aden and learn how AI-powered allocation can:

- Maximize workforce productivity

- Optimize equipment usage

- Cut costs from delays and reassignments

Industry leaders increasingly emphasize that AI-driven allocation is not just a cost saver, but a competitive advantage (PMI, 2023).