🧠 How AI Can Help You Estimate the Bill of Materials Accurately

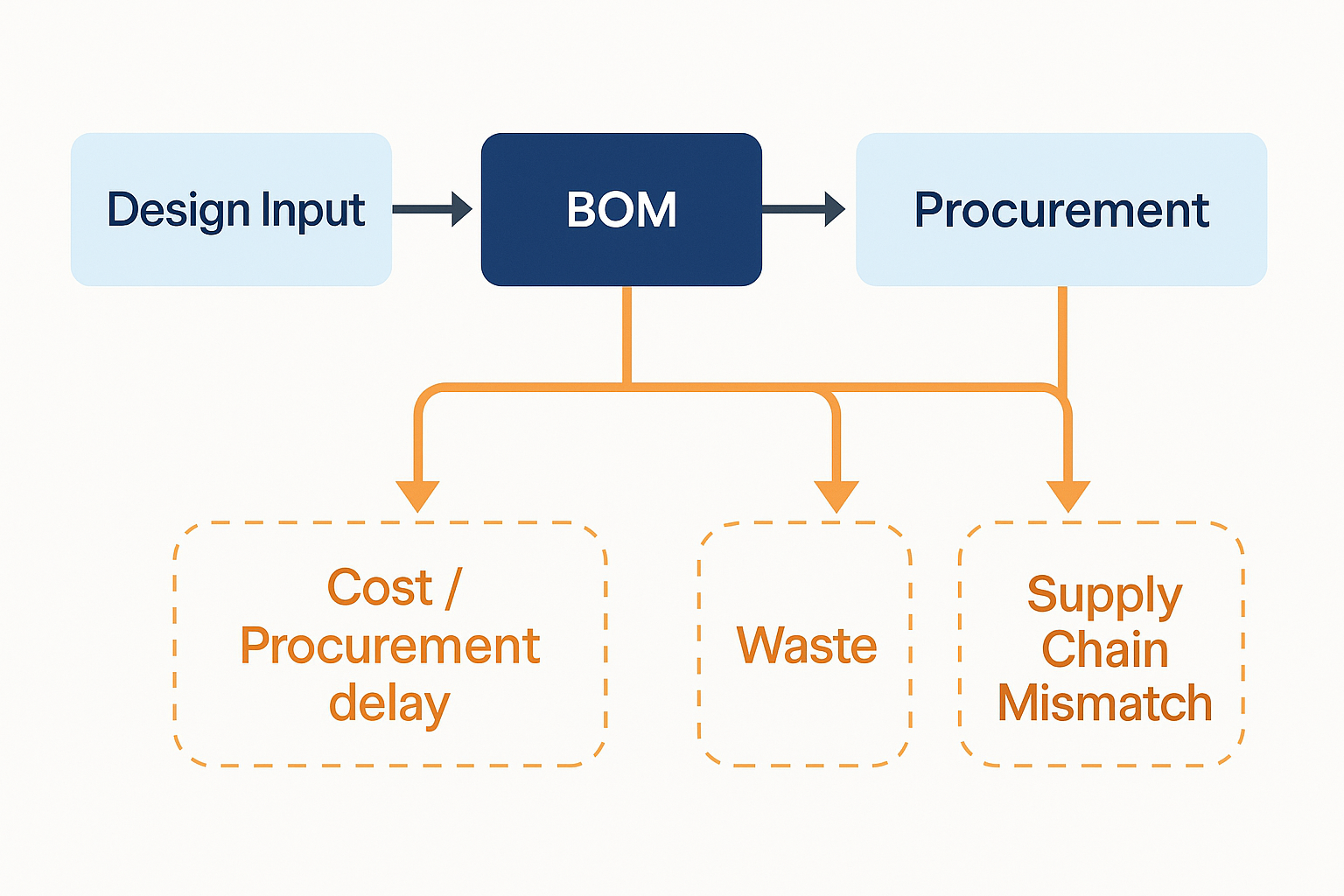

In industries like construction, manufacturing, and energy - where precision defines profitability -accurate Bill of Materials (BOM) estimation isn’t just a technical detail. It’s the backbone of your cost control, project planning, and procurement strategy.

Yet, across industries, BOM inaccuracies are among the most persistent sources of budget overruns and rework.

According to McKinsey & Company (2023), large construction projects typically take 20% longer to complete than scheduled and are up to 80% over budget.

One of the silent culprits behind this inefficiency? ❌ Inaccurate material estimation.

⚙️ What Is a Bill of Materials (BOM)?

A Bill of Materials is a detailed list of raw materials, components, and assemblies required to build, manufacture, or repair a product or project. Think of it as your project’s DNA - every screw, panel, pipe, or circuit neatly documented.

However, traditional BOM estimation often relies on manual data entry, static spreadsheets, and disconnected systems - making it vulnerable to human error, outdated information, and scope drift.

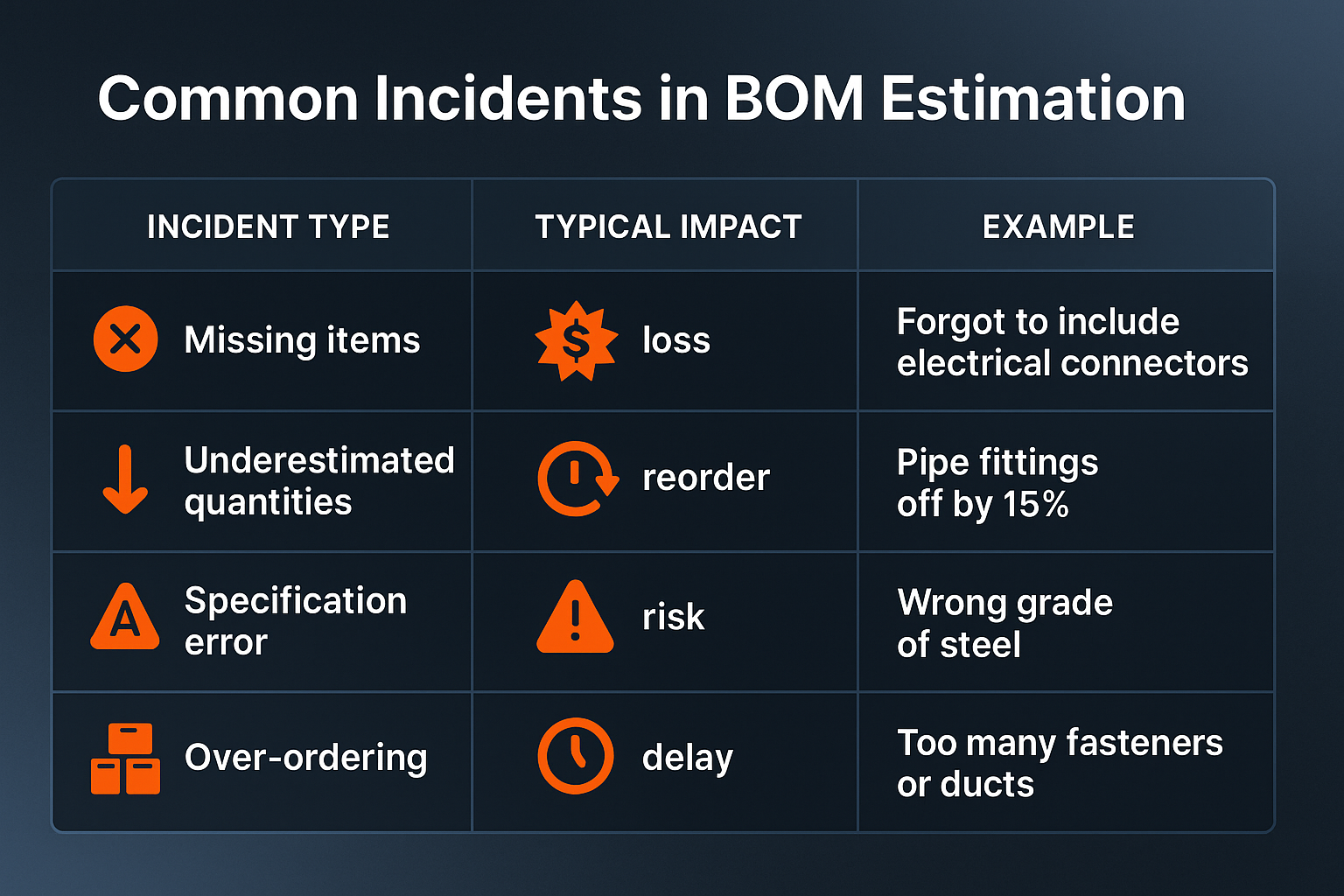

🚨 Common “Incidents” in BOM Estimation

Just like safety incidents, BOM estimation errors can cascade into major operational disruptions. Let’s define these “estimation incidents.”

“In complex, multi-stakeholder projects, a single spreadsheet error can trigger a six-figure cost deviation.”

— Project Controls Lead, Aden Technologies

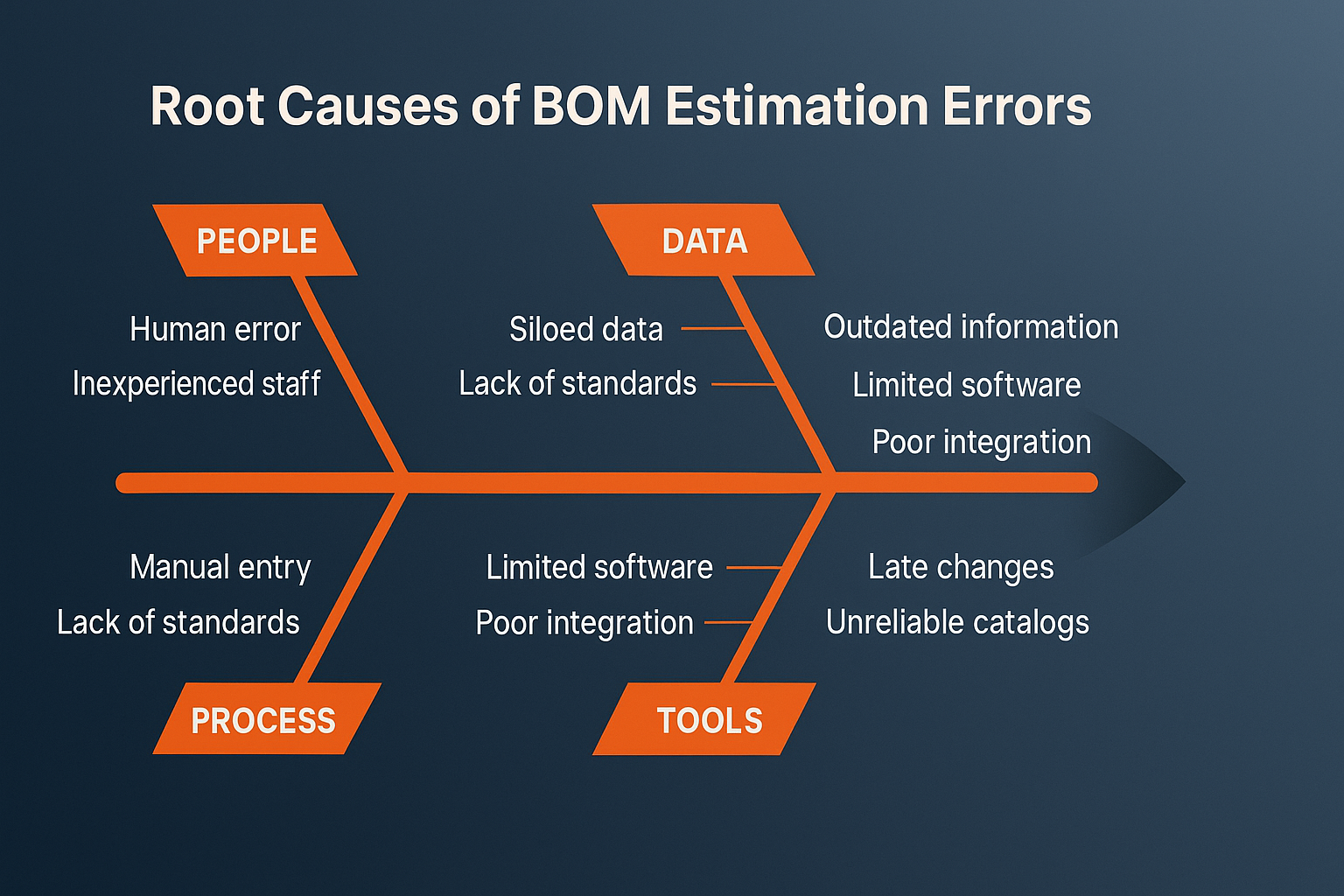

🔍 Root Causes of BOM Estimation Errors

Before solving the problem, we must understand it. Here’s what typically causes BOM deviations:

- 🧩 Fragmented Data Sources — Design drawings, supplier catalogs, and procurement data live in silos.

- ✍️ Manual Processes - Repetitive copy-pasting or inconsistent part labeling leads to errors.

- 🔄 No Feedback Loop - Lessons from previous projects aren’t applied to new estimates.

- 🕰️ Frequent Design Revisions - Design changes often fail to update downstream BOMs.

- 🏗️ Supplier Variability - Different suppliers use different SKUs or material codes.

- 🧮 Complex Dependencies - Nested or conditional parts make manual estimation unreliable.

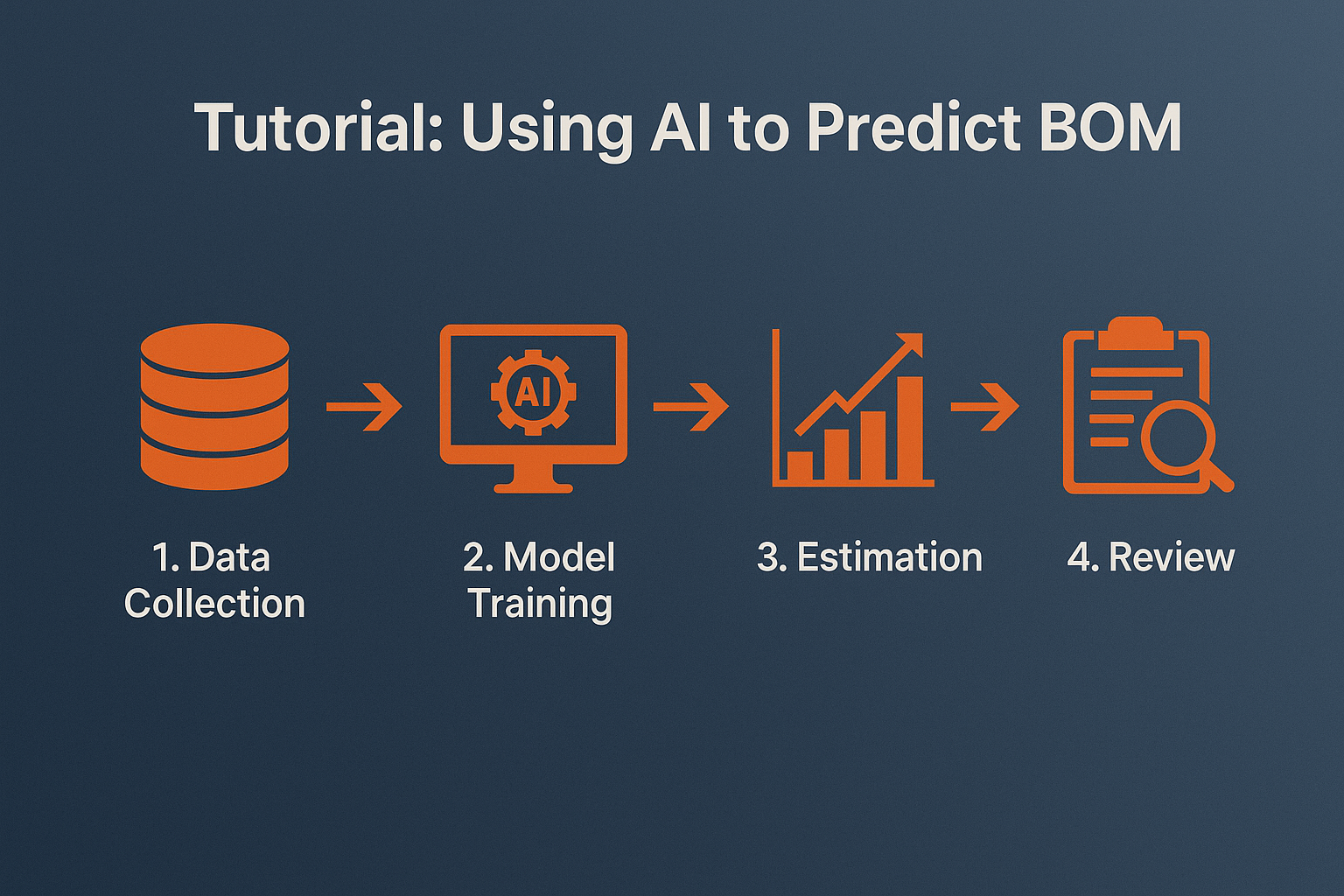

💡 The AI-Driven Solution

AI transforms BOM estimation from reactive to predictive. Let’s explore how.

1️⃣ Automated Data Extraction

AI can read blueprints, CAD files, and PDF specs using computer vision and NLP - identifying parts, materials, and quantities automatically.

“Aden’s AI agents can parse complex design documents and auto-generate preliminary BOMs - cutting estimation time by up to 60%.”

2️⃣ Predictive Calibration Models

By learning from historical data (past estimates vs. actual usage), AI models detect systematic biases and adjust future estimates accordingly.

3️⃣ Missing Component Detection

AI compares current BOMs against similar past projects to flag missing parts or inconsistencies, acting like an intelligent auditor.

4️⃣ Dynamic Variant Management

In configurable projects (e.g., modular builds), AI automatically adjusts quantities and dependencies based on design variations.

5️⃣ Live Supplier Integration

Aden’s system integrates live vendor data to ensure every part number, price, and specification is up-to-date and validated.

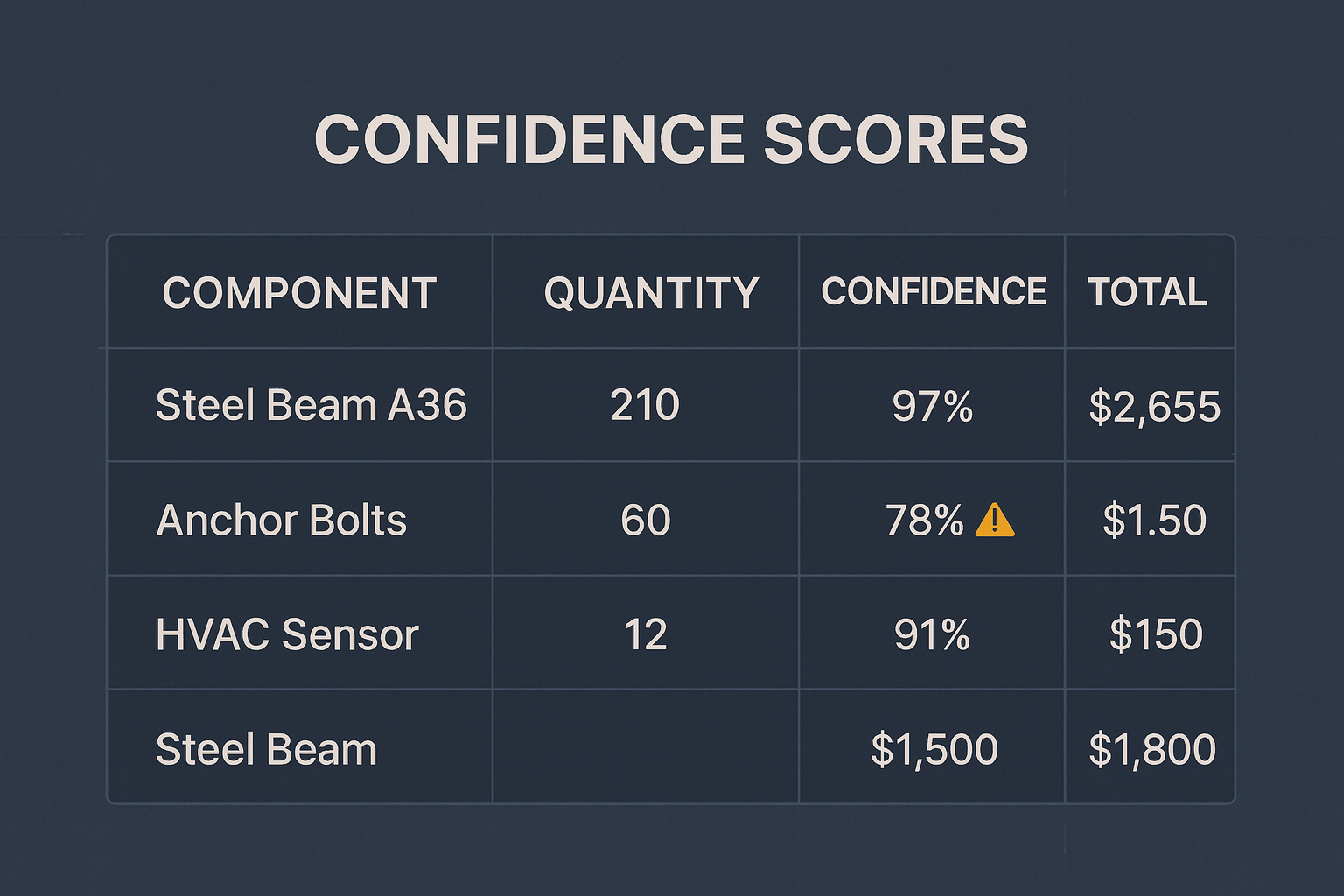

6️⃣ Confidence Scoring & Governance

Each BOM line item gets a confidence score - letting project managers focus review efforts where AI is less certain.

🧰 Why Aden Is Built for This

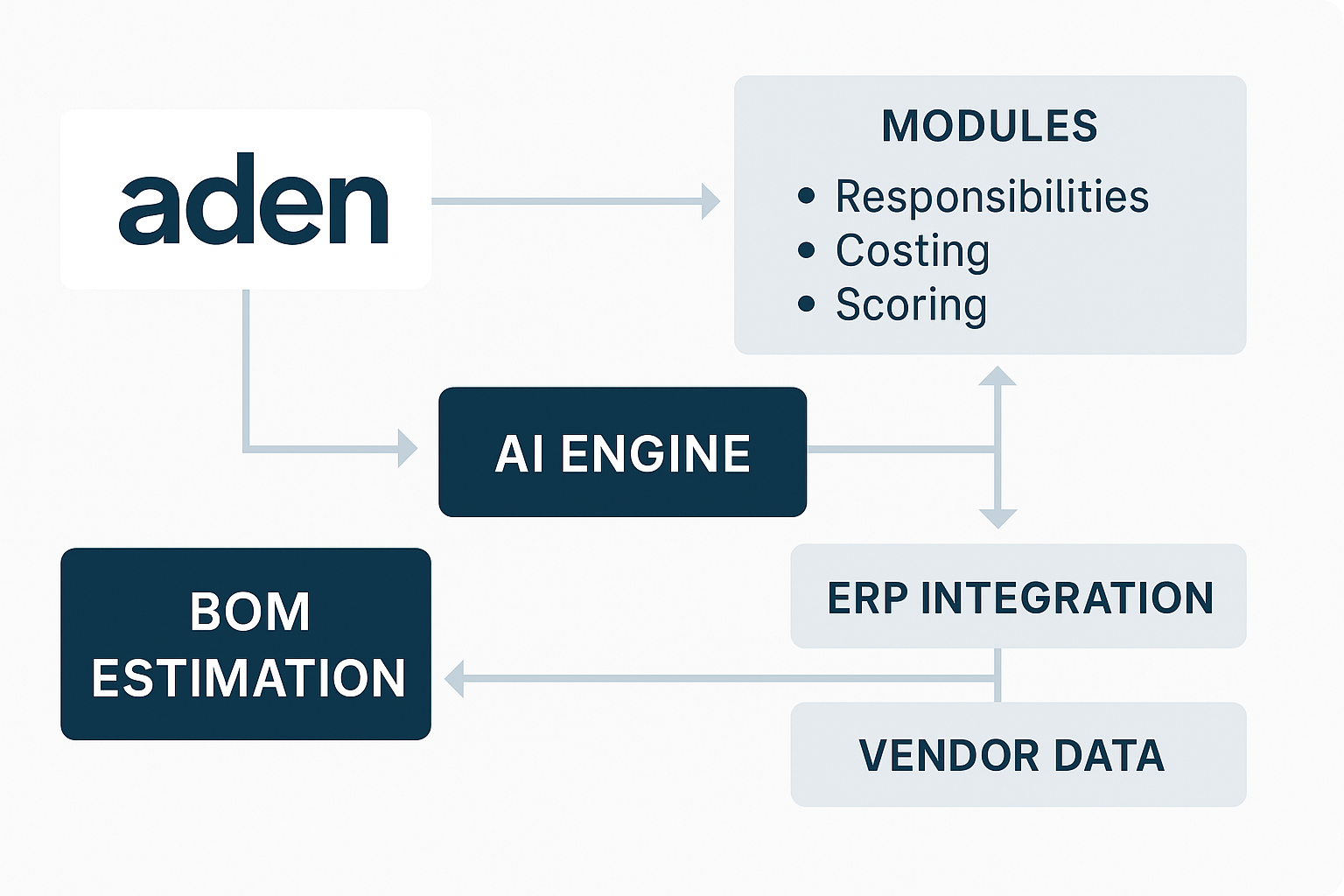

Aden Technologies developed an AI Resource Planning (ARP) system that connects every part of your business — from design to procurement.

Here’s how Aden helps:

- 🤖 AI-Native Estimation Engine — Parses documents, predicts quantities, and flags anomalies.

- 🔗 Unified Platform — Links estimation, procurement, and finance in one ecosystem.

- 📚 Knowledge Agents — Learn from every past project, continuously improving predictions.

- 🧾 Version Control — Tracks every BOM revision, ensuring full traceability.

- 🏢 Governance Tools — Ensure approvals, certifications, and audits align with corporate standards.

“With Aden, your BOMs aren’t static spreadsheets - they’re living, learning models that evolve with every project.”

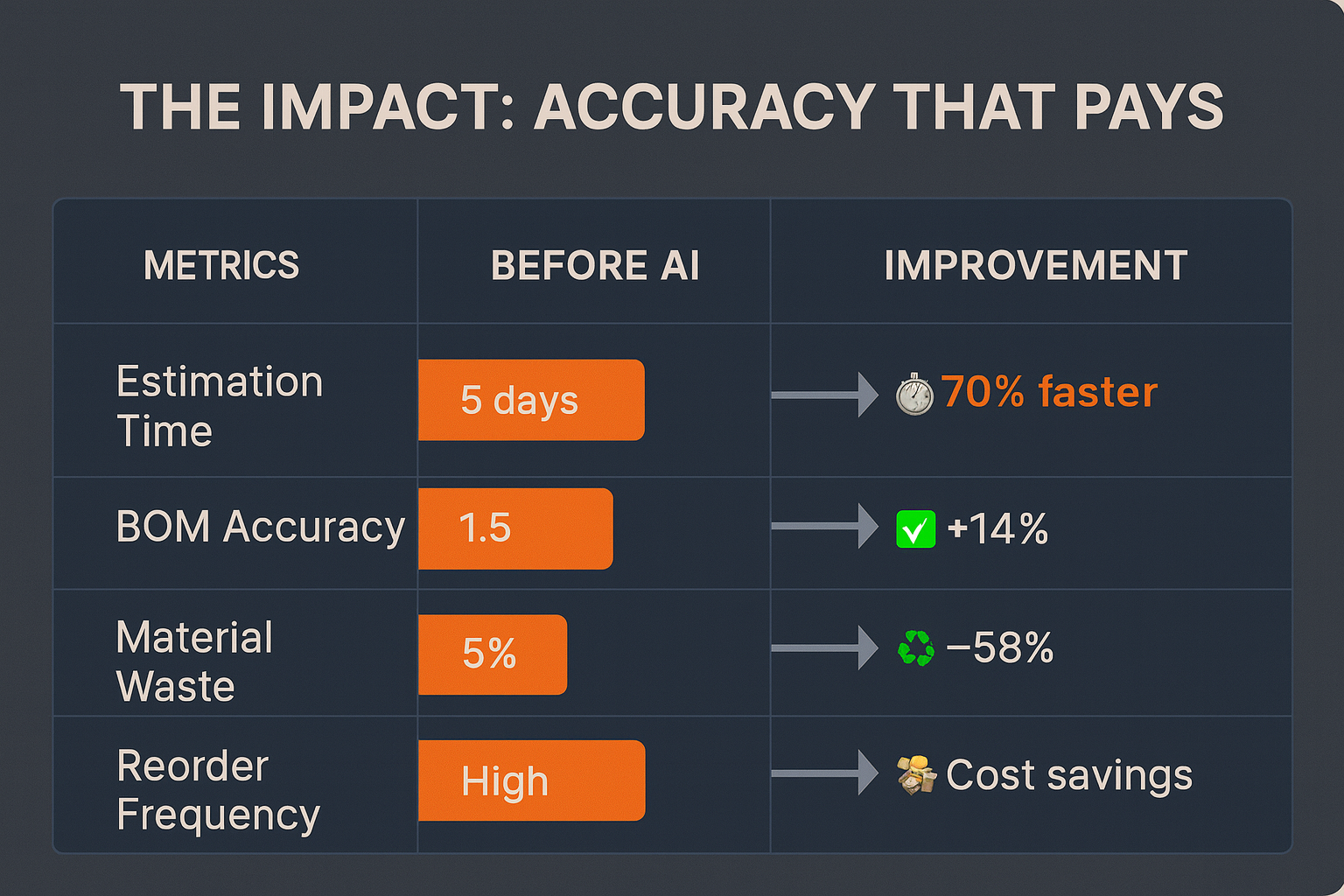

📊 The Impact: Accuracy That Pays

Companies implementing AI-driven estimation have reported:

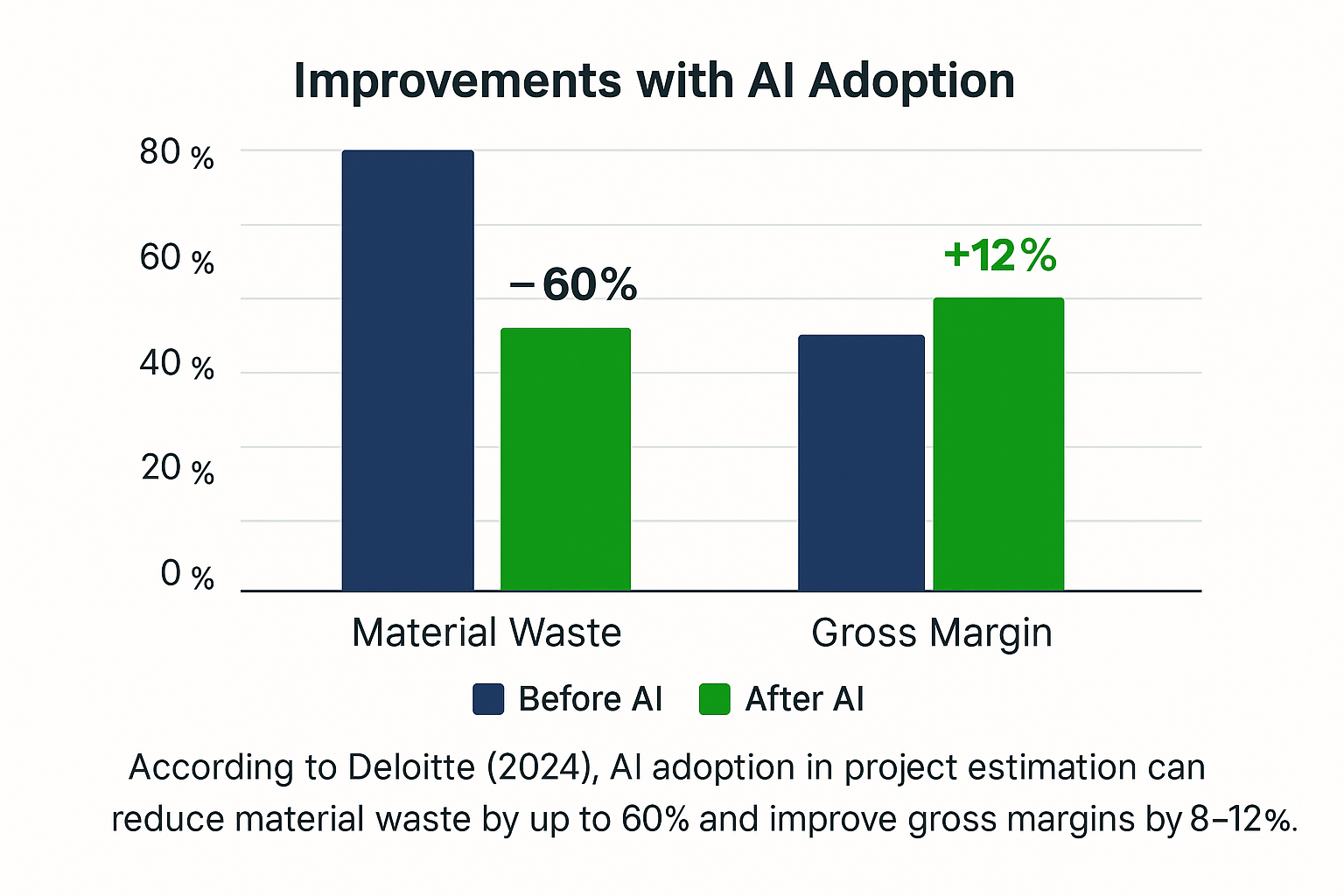

“According to Deloitte (2024), AI adoption in project estimation can reduce material waste by up to 60% and improve gross margins by 8–12%.”

🔮 What does it mean?

Accurate BOM estimation is no longer a tedious manual chore - it’s an intelligent, adaptive process driven by data.

By combining AI’s analytical power with human expertise, organizations can:

✅ Minimize waste

✅ Improve budget predictability

✅ Accelerate project delivery

✅ Build sustainable competitive advantage

🚀 Next Steps

Ready to see how Aden’s AI can transform your estimation workflows?

👉 Schedule a demo with our team.

Or sign up to explore Aden’s AI Resource Planning System and start building smarter today.