🏗️ Introduction

In construction, the field is where the hammer hits the nail and the office is where the numbers get crunched, but when these two worlds don’t talk, costs go up and projects stall. Studies show that poor communication between jobsite crews and office teams is a major driver of delays, rework, and profit fade.

This blog explores the root causes of this communication gap, quantifies the cost of inaction, and offers practical strategies (including training tools) to keep your teams aligned.

🧩 Why the Gap Exists

- Disparate workflows: The office tends to use spreadsheets, planning software and dashboards; the field often uses radios, clipboards, or phones. The mismatch creates information silos.

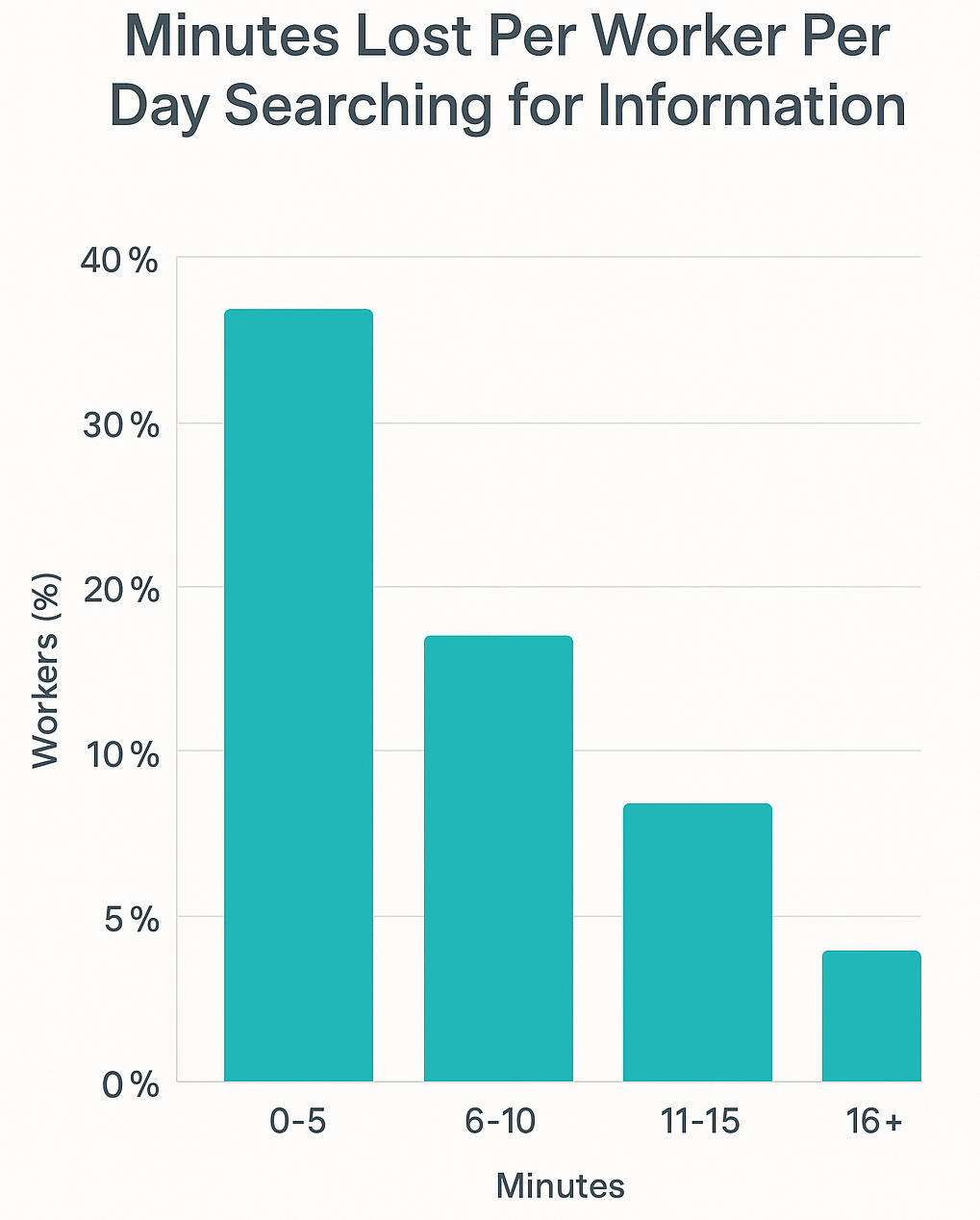

- Delayed or lost updates: “Where’s the latest drawing?” is still common on jobsites. Crews in the U.S. lose up to 90 minutes per worker per day hunting for missing data.

- Cultural/terminology barriers: One study found that for construction engineering grads, interpersonal and oral communication skills were lacking even when technical skills were strong.

- Use of outdated modes: The cost of obsolete communication processes is enormous - one report estimated $31 billion/year lost in the U.S. due to bad or late information in construction.

- “The communication gap between the field and office is a significant contributor to profit fade.” - CLA

💸 The True Cost of Poor Communication

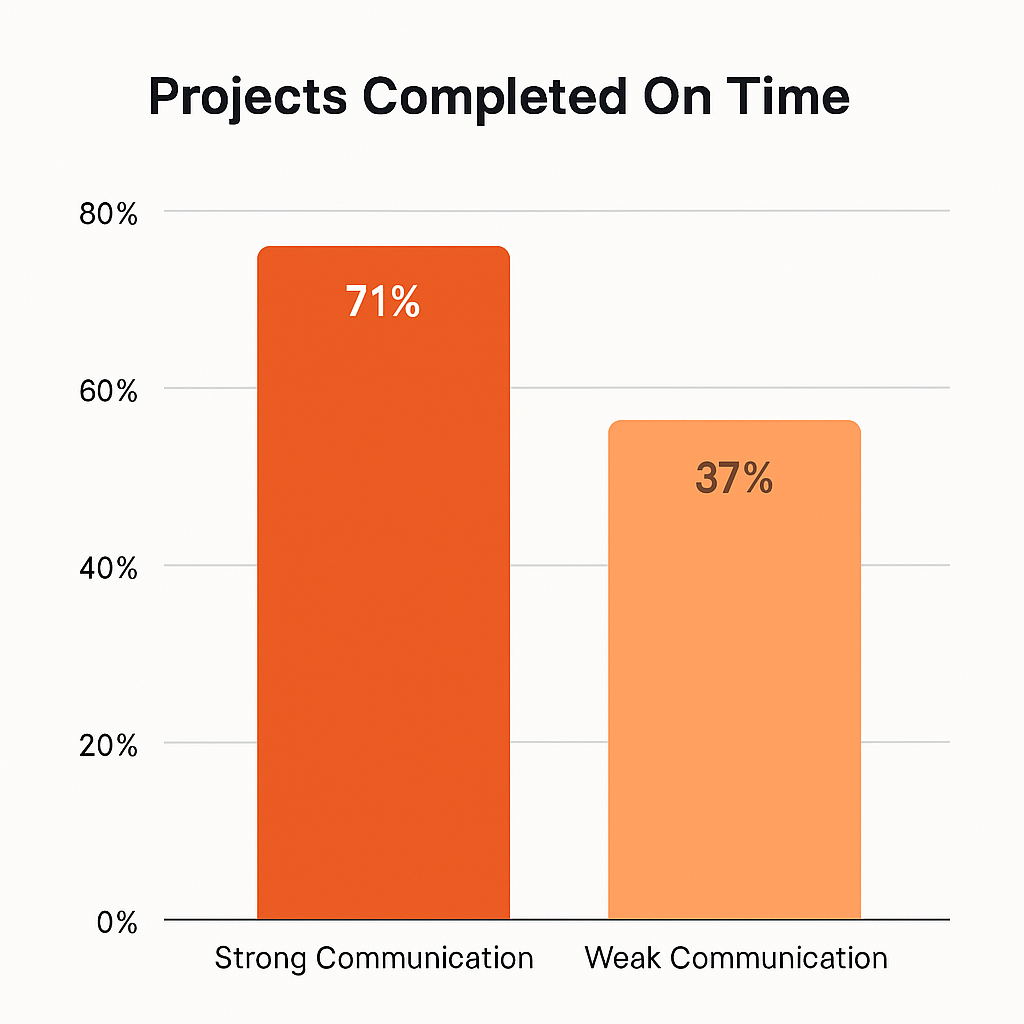

- Projects with weak communication finish on time only 37% of the time; with strong communication, that number rises to 71%.

- Poor communication accounts for ~26‑28% of rework in U.S. construction, with rework costing between 2‑20% of total project value.

- The ripple effects aren’t just financial: morale drops, turnover increases, and workers feel disconnected when decisions in the office don’t translate effectively in the field.

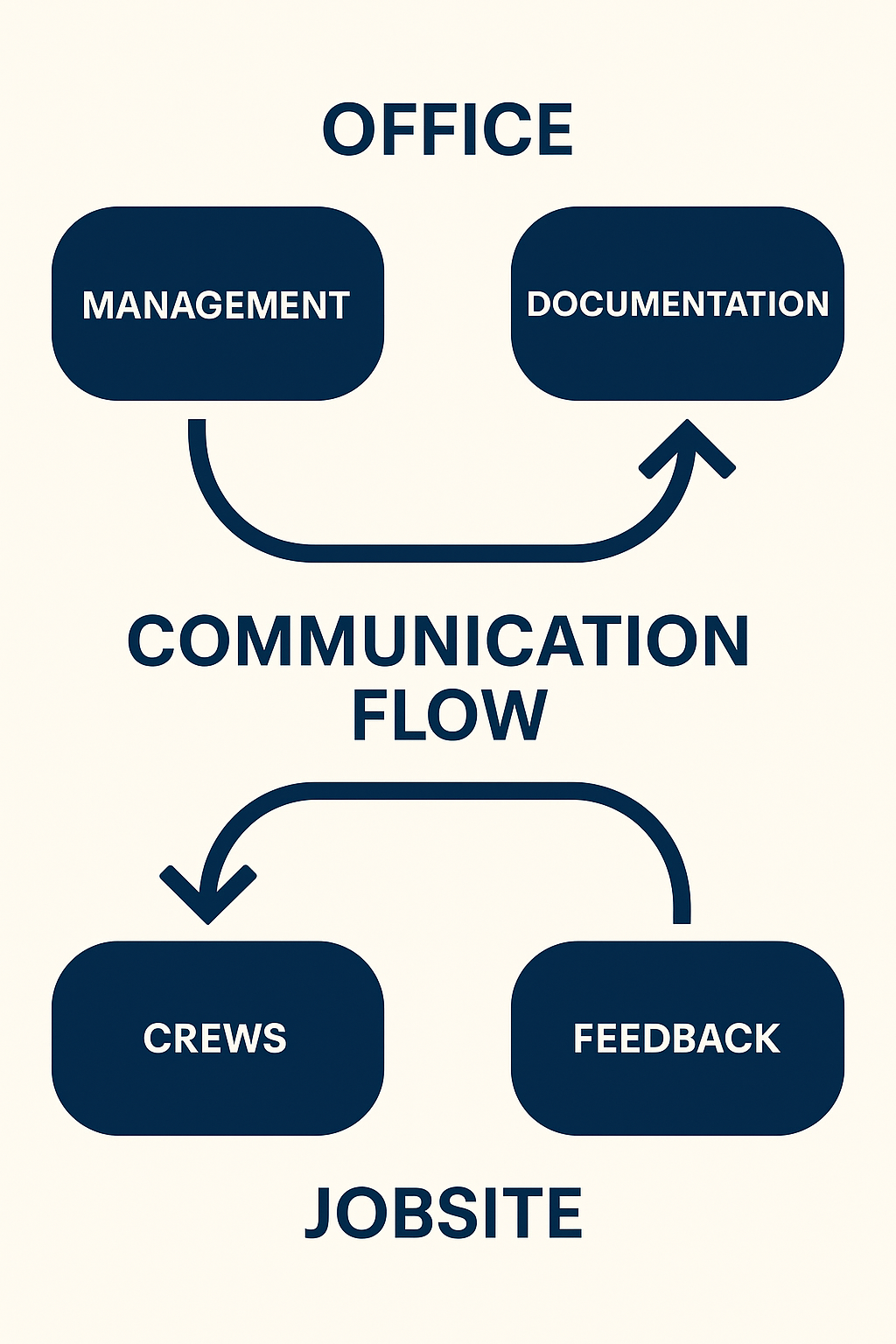

🧠 What Makes a Good “Information Bridge”?

- One source of truth: A unified system where job updates, change orders, safety bulletins and drawings live, and both field and office access them.

- Real‑time updates & confirmation: Ensuring the jobsite gets the latest info, and office teams know it was received.

- Field‑friendly interfaces: Mobile, offline capable, intuitive tools so crews aren’t fighting tech instead of building.

- Training & tools for digital fluency: Even the best software fails if users don’t know how to use it or trust it.

- Feedback loops: Field voices heard in planning; crews feel part of the loop, not acted upon.

🤖 Training as the Catalyst for Alignment

Training is often overlooked, but when done right, it becomes the bridge between strategy and execution. Instead of expecting crews to “learn it in the field,” modern programs can:

- Bring the office language to the jobsite (and vice‑versa) so everyone “speaks the same project.”

- Use scenario‑based learning on how changes propagate from office to field (and the risks when they don’t).

- Provide mobile, just‑in‑time refreshers for supervisors and crews to keep everyone aligned.

- By training both field and office teams together (or with aligned materials), you keep the chain of action tighter, decisions smarter, and outcomes more predictable.

📈 What Success Looks Like

- Up to 30% fewer delays when communication is optimized.

- 20% drop in rework when updates flow seamlessly and everyone’s on the same page.

- Higher team retention and better morale because workers feel included in the process.

- Safer jobsites: when info flows, hazards are identified sooner and managed proactively.

🤝 Conclusion

Bridging the gap between the office and jobsite isn’t just about tech; it’s about alignment. It’s the difference between a site that reacts and a site that builds. Training, culture, and process must combine with technology to create a communication flow that doesn’t just exist, but works. When the front line and the back office genuinely talk and listen, you’ll find schedules smoother, teams stronger, and margins healthier.